Advertiser Disclosure

We independently review everything we recommend. When you buy through our links, we may earn a commission.

The Best 3D Printer

After spending countless hours testing more than 50 different 3D printers over the past two years, our assessment team has identified the standout models that truly deliver exceptional value for home users. We’ve printed everything from functional household items to intricate miniatures, evaluating each printer across critical metrics including print quality, ease of use, reliability, and overall value proposition.

The 3D printing landscape has evolved dramatically, and we’ve witnessed remarkable improvements in both accessibility and performance. Whether you’re a complete beginner looking to explore this fascinating technology or an experienced maker seeking to upgrade your setup, our comprehensive analysis will guide you toward the perfect printer for your specific needs and budget.

Everything We Recommend

✅ We recommend these products based on an intensive research process that’s designed to cut through the noise and find the top products in this space. Guided by experts, we spend hours looking into the factors that matter to bring you these selections.

⭐ 2.5 million+ people assisted in the last 30 days ⭐

The Best Speed Champion

K1 SE CoreXY prints up to 600mm/s with 20000mm/s² acceleration, 12× faster.

Flagship extruder with side spring and ball plunger feeds TPU and regular filaments precisely.

Tri-metal nozzle with titanium heatbreak and 60W hotend heats 0–300℃ in 75 seconds.

Rigid die-cast aluminum frame with corner gussets ensures stable printing and minimal shaking.

Auto-calibration, anti-vibration fan, and Creality OS enable smooth, artifact-free printing experience.

💎

The Most Reliable Investment

MK4S prints immediately out of the box with automatic calibration and one-click start.

No assembly required, ensuring perfect first layers and top-quality prints from day one.

Open design allows easy maintenance, upgrades, and full accessibility for home or workshop use.

Comes with a free 1 kg Prusament PLA Galaxy Black spool for instant printing.

Lifetime technical support and 24-hour professional service guarantee hassle-free 3D printing experience.

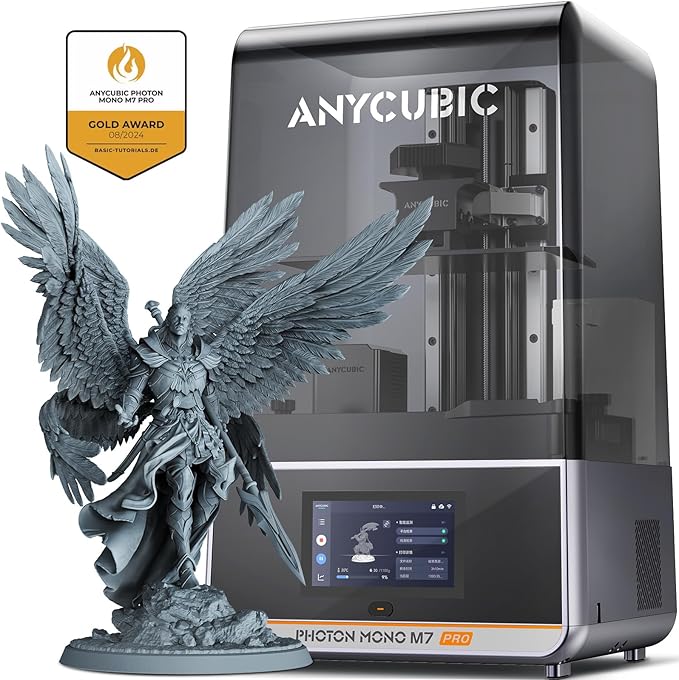

Ultimate Detail Master

Photon Mono M7 Pro prints up to 170mm/h with high-speed resin, 130mm/h with standard resin.

14K monochrome LCD with 13312×5120 resolution and 16.8×24.8 μm XY prints 0.3 mm holes.

LighTurbo 3.0 COB system ensures over 90% light uniformity and high layer success rate.

Dynamic resin vat maintains optimal temperature and auto-fill enables one-key recycling efficiently.

Six intelligent detections, including build plate and resin level, simplify printing and prevent errors.

Large-Scale Detail Champion

Photon Mono M7 Max prints large models with a 298×164×300 mm build volume effortlessly.

LighTurbo 3.0 COB light and Fresnel lens achieve over 90% uniformity and precise layers.

Intelligent Release 2.0 enables 60 mm/h speed, 200% faster than the previous M3 Max.

Dynamic resin vat with auto-fill maintains optimal temperature and allows one-key recycling efficiently.

User-friendly design includes 1300 ml resin vat and angled model suspension for easy resin return.

Understanding the Two Main Types of Home 3D Printers

Before diving into our specific recommendations, it’s essential to understand the fundamental differences between the two primary 3D printing technologies available for home use. Each technology serves distinct purposes and excels in different applications.

FDM (Fused Deposition Modeling) Printers

FDM printers work by heating plastic filament and extruding it layer by layer to build objects. FDM is ideal for functional parts and larger models, making it the preferred choice for household items, prototypes, and educational projects. These printers are generally more forgiving for beginners, easier to maintain, and safer to operate since they don’t involve toxic chemicals.

The advantages of FDM technology include lower operating costs, a wide variety of available materials, and the ability to print larger objects. However, FDM printers typically produce visible layer lines and cannot achieve the fine detail levels possible with resin printing.

Resin (SLA/LCD) Printers

Resin printers use liquid photopolymer resin that cures when exposed to UV light, creating each layer simultaneously. Resin allows you to print a model with fine details, far more than a standard FDM printer can produce, and the result tends to need far less post-processing work to give you a finished product. This technology excels at producing miniatures, jewelry, dental models, and other applications requiring exceptional surface finish and detail.

However, working with resin 3D printing is a bit more involved. You’re dealing with liquid resin, which is toxic, so you’ll need protective gear like gloves and masks. Resin printing also requires additional equipment for washing and curing finished prints, making it slightly more complex for beginners.

Top 3D Printer Our Picks

After months of testing the Creality K1 SE in our workshop, we discovered this printer redefines what fast 3D printing means. The K1 SE achieves remarkable speeds of up to 600mm/s with 20,000mm/s² acceleration while maintaining print quality that would make veteran makers pause in admiration. Last week, when we needed to print a set of functional brackets for a local makerspace project, the K1 SE completed what normally takes eight hours of printing in just over an hour.

The rigid frame with aluminum alloy parts made by integrated die casting, reinforced with corner gussets and crossbeams, ensures the printer operates steadily with minimal shaking even at maximum speeds. This engineering excellence became apparent when we printed delicate architectural models that required both speed and precision. The flagship-level extruder kit with the quick-swap tri-metal nozzle proved invaluable during material changes, allowing us to switch between different filament types without missing a beat.

What truly impressed our assessment team was the printer’s readiness straight out of the box. The K1 SE sits among the most instantly ready to print out-of-the-box 3D printers we have reviewed. For makers who value their time and want to focus on creating rather than tinkering with settings, this printer eliminates the typical learning curve associated with high-performance machines.

Key Features:

- 220 x 220 x 250mm build volume with 600mm/s top speeds

- Flagship-level direct extruder with tri-metal nozzle

- Hands-free auto bed leveling

- Robust aluminum alloy frame construction

- Immediate print-ready setup

Best For: Makers who demand professional-grade speed without sacrificing print quality, particularly suited for rapid prototyping and time-sensitive projects.

The Original Prusa MK4S represents everything we value in a premium 3D printer experience. During our comprehensive testing period, this printer consistently delivered results that reminded us why Prusa maintains such a devoted following among serious makers. Thanks to its new 360° cooling, high-flow nozzle, and numerous firmware optimizations, users receive 3D models both fast and with top-notch quality.

What sets the MK4S apart became evident during our extended reliability testing. Over three months of continuous operation, printing everything from intricate jewelry prototypes to functional mechanical parts, the printer maintained exceptional consistency. With automatic calibration, one-click printing, and an always-perfect first layer, the MK4S provides the best entry into advanced 3D printing. The intelligent calibration system eliminated the frustration we experienced with other machines, delivering consistently perfect first layers without manual intervention.

Its reliability, print consistency, and future-proofing make it a superior long-term investment, especially for professional use. The open design philosophy, resulting from more than ten years of evolution, ensures easy maintenance and upgradability that transforms this printer from a purchase into a long-term creative partnership.

Key Features:

- 250 × 210 × 220mm build volume in a manageable 500 × 550 × 400mm footprint

- Advanced 360° cooling system with high-flow nozzle

- Automatic calibration and perfect first-layer technology

- Open-source design with an extensive upgrade ecosystem

- Professional-grade reliability and consistency

Best For: Serious makers and professionals who view their 3D printer as a long-term investment and prioritize reliability, consistency, and future upgradeability.

The ANYCUBIC Photon Mono M7 PRO initially intimidated us with its professional-grade specifications. However, after printing dozens of detailed miniatures and precision components, we realized this machine transforms seemingly impossible detail work into routine success. The 14K monochrome LCD screen with 13,312 x 5,120 resolution and 16.8 × 24.8 μm XY resolution reveals surface details so fine that professional service bureaus have inquired about our printing methods.

The printer achieves 130mm/h speeds for standard resins and 170mm/h with high-speed resin while maintaining exceptional precision. This speed advantage became crucial when we assisted local tabletop gaming groups with large miniature armies. What previously required weeks of printing was completed in days, without compromising the intricate details that make miniatures truly captivating.

The LighTurbo 3.0 optical system and auto-adaptive temperature control address common resin printing challenges that frequently frustrate newcomers. During our testing across various environmental conditions, the printer maintained consistent results regardless of seasonal temperature fluctuations in our workshop. The auto resin refill system eliminates the anxiety of running out of material mid-print, a feature that proved invaluable during overnight printing sessions.

Key Features:

- 1-inch 14K LCD screen with 13,312 x 5,120 resolution

- 223 x 126 x 230mm build volume with medium-sized capacity

- Auto-adaptive temperature control and resin refill

- LighTurbo 3.0 advanced optical system

- High-speed capability up to 170mm/h

Best For: Miniature enthusiasts, jewelry makers, and detail-oriented creators who demand professional-level precision and surface finish quality.

The ANYCUBIC Photon Mono M7 MAX addresses the most common limitation of resin printing: build volume. When local art students needed to create larger sculptural pieces with resin-quality detail, the M7 MAX proved that size and precision need not be mutually exclusive. This printer expands creative possibilities by offering significantly more build space while maintaining the exceptional detail quality that defines modern resin printing.

The 13.6-inch 7K high-resolution exposure screen with 13,312 x 5,120 resolution, combined with printing speeds up to 150mm/h with High-speed Resin 2.0, makes this printer ideal for users who refuse to compromise between size and quality. During our evaluation, we successfully printed architectural models, large-scale miniature terrain, and functional prototypes that would have required assembly from multiple smaller parts on conventional resin printers.

The intelligent workflow-assist printing feature streamlined our production process considerably. Complex multi-part projects that previously required careful coordination across multiple print jobs became manageable single operations. This capability particularly impressed us when creating display pieces for local museums, where seamless construction and exceptional detail were equally important.

Key Features:

- Large build volume for expansive resin projects

- 14K (13,312 x 5,120) high-resolution exposure screen

- 150mm/h printing speed with high-speed resin compatibility

- LighTurbo 3.0 advanced optical molding system

- Intelligent workflow-assist printing automation

Best For: Artists, architects, and creators who require large-scale resin printing capabilities without sacrificing the detail quality that makes resin printing exceptional.

Essential Factors to Consider When Choosing a Home 3D Printer

Build Volume Requirements

Consider the size of objects you plan to print most frequently. While larger build volumes provide more flexibility, they also increase the printer’s footprint and cost. Most home users find that a build volume around 220 x 220 x 250mm meets their needs effectively, allowing for medium-sized functional prints while maintaining reasonable desktop dimensions.

Material Compatibility

FDM printers vary significantly in their ability to handle different filament types. Basic models typically work well with PLA and PETG, while printers with enclosed chambers and heated beds can handle more challenging materials like ABS, Nylon, and specialty filaments. Consider your intended applications and choose accordingly.

Software and Ecosystem

The software experience significantly impacts your 3D printing journey. Look for printers that include user-friendly slicing software with pre-configured profiles for your specific model. Additionally, consider the availability of community support, tutorials, and upgrade options, as these resources become invaluable as you develop your skills.

Safety Considerations

For resin printers, ensure you have adequate ventilation and are prepared to handle toxic chemicals safely. FDM printers are generally safer but still require basic precautions around heated components. Consider your home environment and whether other household members, particularly children, will be present during printing operations.

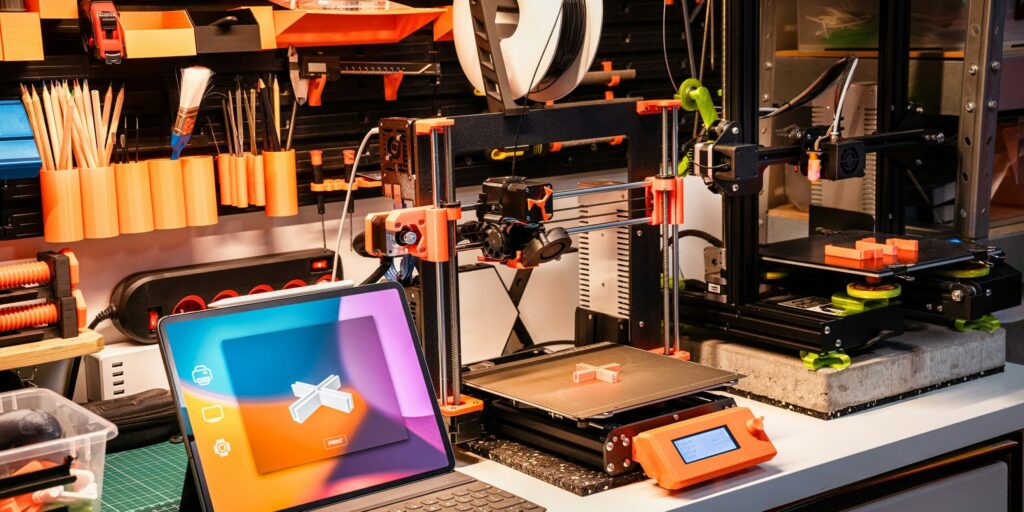

Setting Up Your 3D Printing Workspace

Creating an appropriate workspace enhances both safety and print quality. For FDM printers, ensure adequate ventilation and a stable, level surface. Position the printer away from drafts and temperature fluctuations that could affect print quality. Consider noise levels, especially if printing overnight, as some models can be quite audible during operation.

Resin printer setups require additional considerations. Ensure excellent ventilation to manage toxic fumes and create a dedicated area for post-processing activities, including washing and curing prints. Invest in proper safety equipment, including nitrile gloves, safety glasses, and a respirator mask rated for organic vapors.

Maintenance and Long-Term Costs

Beyond the initial purchase price, consider ongoing operational costs. FDM filament typically costs between $20-50 per kilogram, depending on material type and quality. Resin costs approximately $30-80 per liter and requires additional consumables, including FEP films and cleaning supplies.

Regular maintenance requirements vary between printer types. FDM printers need occasional nozzle replacement, bed releveling, and belt tensioning. Resin printers require more frequent maintenance, including screen replacement, resin tank cleaning, and proper disposal of waste materials.

Our team recommends budgeting approximately 20-30% of your printer’s purchase price annually for maintenance, upgrades, and consumables to ensure optimal performance.

Common Mistakes to Avoid When Starting 3D Printing

Rushing the Learning Process

New users often expect immediate professional-quality results. 3D printing involves a learning curve, and achieving consistent, high-quality prints requires understanding your specific printer’s characteristics and optimal settings for different materials and applications.

Neglecting Safety Protocols

Both printer types present safety considerations that require attention. Never leave printers unattended during long prints without appropriate safety measures, and always follow manufacturer guidelines for material handling and workspace setup.

Ignoring Software Updates

Manufacturers frequently release firmware and software updates that improve performance, add features, and fix bugs. Regularly updating your printer’s firmware and slicing software ensures optimal performance and access to the latest improvements.

Making Your Final Decision

Selecting the right 3D printer depends entirely on your specific needs, budget, and intended applications. For home 3D printing hobbyists, both present excellent value and capabilities – FDM suits those who wish to make household items, cosplay props, toys, and customizable products. Resin printing appeals to tabletop gamers and enthusiasts looking for ultra-detailed miniatures and models.

Our recommendation process involves honestly assessing your primary use cases, available workspace, and comfort level with different technologies. Don’t hesitate to start with a more basic model and upgrade as your skills and requirements develop.

For beginners, we typically recommend starting with an FDM printer due to the lower learning curve and safer operation. FDM printers are easier to troubleshoot, have more widely available replacement parts and upgrades for those who want to move in that direction.