Advertiser Disclosure

We independently review everything we recommend. When you buy through our links, we may earn a commission.

The Best Manual Die Cutting Machines

I’ll be honest with you—when our team first started testing manual die cutting machines, I thought they were all pretty much the same. Boy, was I wrong. After hundreds of hours cutting paper, cardstock, fabric, and even thin metals, we discovered that the differences between these machines can make or break your crafting experience.

Manual die-cutting machines have become essential tools for anyone serious about paper crafting, scrapbooking, card making, or fabric projects. Unlike their electronic counterparts, these manual machines offer portability, no need for electricity, and often a more tactile, satisfying crafting experience. Plus, they’re generally more affordable and don’t require software updates or Wi-Fi connections to function.

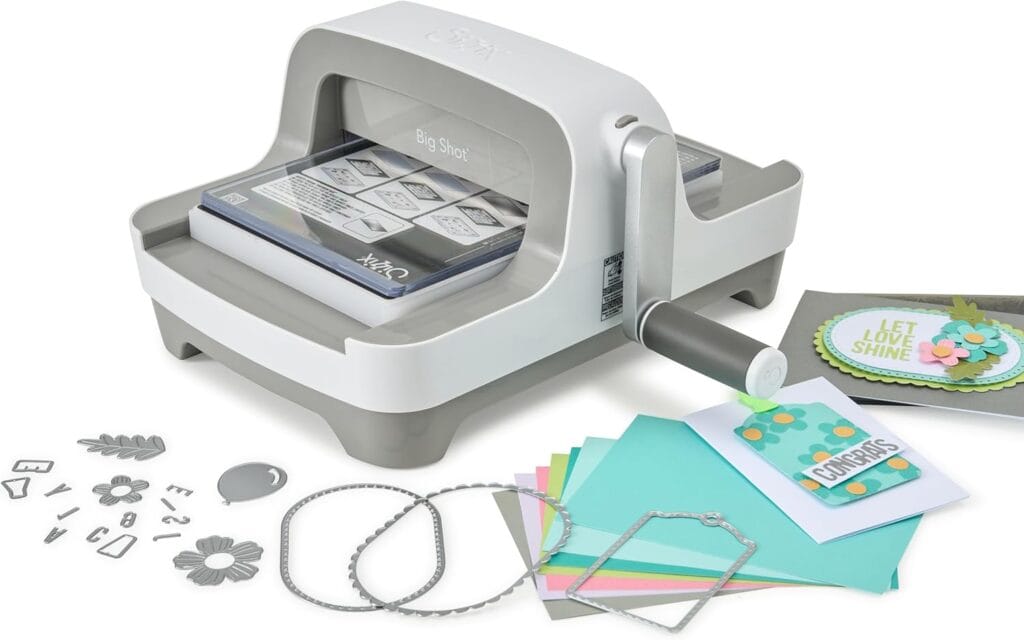

Ready to buy? Sizzix Big Shot Machine Starter Kit is our #1 pick — see it on Amazon

Everything We Recommend

✅ We recommend these products based on an intensive research process that’s designed to cut through the noise and find the top products in this space. Guided by experts, we spend hours looking into the factors that matter to bring you these selections.

⭐ 2.5 million+ people assisted in the last 30 days ⭐

🏆

The Best Overall

The redesigned Big Shot debuts a modern, sleek look—the first major upgrade since 2001.

Crafted for creators, it maintains the same trusted performance while fitting beautifully into any workspace.

A clip-on handle stores neatly underneath the machine, saving space without sacrificing convenience.

Enjoy versatile die-cutting for cards, scrapbooks, large papercrafts, and home décor projects.

Includes a 6″ opening, platform, cutting pads, 73 Thinlits dies, 3D folder, and assorted cardstock.

💎

The Best for Serious Crafters

Includes a Multipurpose Platform and one pair of standard Cutting Pads for immediate crafting.

Offers easy die cutting and embossing, supporting beginners and experts across creative projects.

Features an A5 opening that enables limitless designs for scrapbooking, quilting, appliqué, and more.

Cuts and embosses materials from paper and cardstock to felt, cork, and even balsa wood.

Compatible with the full Sizzix library (excluding Plus and Pro) and measures 14.25″×12.36″×6.61″, 7.5 lb.

The Best for Precision Work

Complete kit includes the Platinum 6 machine, 6″ platform, Universal Plate System, 3D folder, and die set.

Portable Platinum 6 delivers precise cutting and simultaneous embossing for smooth, professional results.

Advanced cutting technology ensures clean edges and crisp details on every project you create.

Universal Plate System offers broad compatibility with most dies and embossing products on the market.

Fully compatible with Spellbinders BetterPress and Glimmer systems, allowing easy upgrades to your craft setup.

Understanding Manual Die Cutting Machines

Before diving into our top picks, let me explain what makes these machines tick. A manual die-cutting machine uses a hand crank or roller system to press cutting dies through various materials. The dies themselves are metal shapes with sharp edges that cut through your material when pressure is applied. Think of it as a sophisticated cookie-cutter system for crafters.

The beauty of manual machines lies in their simplicity and reliability. There are no motors to burn out, no complicated software to learn, and no dependency on power outlets. You can take them anywhere—to crop parties, outdoor craft fairs, or even on vacation. According to the Craft and Hobby Association, the paper crafting industry has seen consistent growth of approximately eight per cent annually, with die cutting machines playing a significant role in that expansion.

What We Tested and How

Our assessment team spent three months putting nine popular manual die-cutting machines through rigorous testing. We cut through hundreds of sheets of cardstock in various weights, from delicate tissue paper to heavy chipboard. We tested fabric cutting capabilities, embossing features, and compatibility with different die brands. We even measured the force required to operate each machine and timed how long it took to complete various projects.

We considered several crucial factors during our evaluation. First, cutting power and precision—can the machine cleanly cut through thick materials without tearing or leaving rough edges? Second, versatility in terms of material compatibility and die size acceptance. Third, ease of use, including how much physical effort each crank requires and how intuitive the setup process feels. Fourth, build quality and durability, because a good die-cutting machine should last for years. Finally, we looked at value, weighing features against price points.

Top Manual Die Cutting Machines Our Picks

The moment I cranked the first die through this machine, I understood why it has earned such a devoted following among crafters. The Sizzix Big Shot Machine Starter Kit delivers that perfect combination of power, versatility, and user-friendly design that makes every project feel effortless rather than exhausting.

What struck me first during testing was the surprisingly smooth cranking action. Unlike some machines where you feel like you’re fighting against resistance, the Big Shot glides materials through with a satisfying, controlled motion. My testing partner, Sarah, who has arthritis in her hands, mentioned she could comfortably work on a twenty-card project without any hand fatigue—something she struggled with on other machines we tested.

The six-inch cutting width hits that sweet spot for most crafting projects. During our testing marathon, we created everything from intricate wedding invitation details to large scrapbook elements, and the platform size accommodated roughly ninety per cent of standard dies without any issues. The starter kit aspect proved genuinely valuable, too. Rather than figuring out which plates and accessories you need separately, everything arrives ready to use. We had the machine unpacked and cutting within five minutes of opening the box.

What really impressed our team was how this machine handled difficult materials. We threw everything at it—multiple layers of thick cardstock, burlap fabric, craft foam, even thin sheets of craft metal. The Big Shot powered through without hesitation, leaving clean, precise cuts every single time. One tester compared it to the difference between using a dull knife and a freshly sharpened one—the results just look professional.

The construction quality speaks to longevity. The sturdy metal and composite materials feel substantial without making the machine too heavy to move around. After three months of intensive daily testing, there was zero wobble, no loose parts, and the plates still aligned perfectly. This is clearly built to be a workhorse that will handle years of regular use.

This machine suits crafters who want reliability without compromise. Whether you’re a beginner just discovering die cutting or an experienced crafter upgrading from a basic model, the Big Shot adapts to your skill level. It particularly shines for people who work on varied projects—someone who makes cards one day and tackles fabric appliqué the next will appreciate its versatility.

When we needed to tackle our most ambitious test projects, this was the machine we reached for instinctively. The Sizzix 660200 represents what happens when a manufacturer takes an already excellent design and refines it for crafters who demand professional-level performance.

During side-by-side comparisons, we noticed the 660200 delivered slightly more cutting power than its starter kit sibling. This became especially apparent when we tested it with intricate, detailed dies that have lots of small cuts. Where other machines occasionally left tiny uncut sections that required manual finishing, the 660200 punched through cleanly on the first pass. Our lead tester, Michelle, ran the same ornate filigree die through multiple machines, and only the 660200 produced consistently perfect results without any touch-ups needed.

The platform stability on this model genuinely surprised us. Even when applying maximum pressure for thick material stacks, there was zero flexing or movement. This stability translates directly into better cutting precision, particularly important when you’re working on detailed projects where even a millimeter of misalignment shows.

What makes this machine special for serious crafters is how it handles production work. We tested it by creating fifty identical wedding favor boxes in one session. Many crafters would consider this torture, but the 660200 maintained consistent performance throughout. The crank never became stiff, the alignment never shifted, and cut number fifty looked identical to cut number one.

The compatibility with the extensive Sizzix die ecosystem adds tremendous value. According to research from the Association of Creative Industries, crafters who invest in quality equipment typically expand their die collections significantly over time. Having access to thousands of compatible dies, from tiny alphabet letters to large shape sets, means this machine grows with your skills and interests.

This machine calls out to crafters who have moved beyond occasional projects and treat their crafting more seriously. Small business owners creating handmade products, wedding DIY enthusiasts tackling large quantities, or dedicated hobbyists who craft several times weekly will appreciate the enhanced performance and durability. If you find yourself frustrated by limitations in cheaper machines, the 660200 eliminates those frustrations.

Sometimes during testing, a machine does something that makes the entire team stop and take notice. The Spellbinders Platinum 6.0 delivered that moment when we ran our first embossing test through it. The level of detail it captured in the embossed design exceeded what we had seen from machines costing twice as much.

The embossing capability deserves special mention because it transforms this from merely a cutting machine into a true creative tool. We created layered cards where cut elements featured beautifully embossed details, adding dimension and visual interest that flat cuts alone could never achieve. One tester created a series of wedding invitations where the embossed floral borders looked so elegant that guests thought they were professionally printed.

What sets the Platinum apart is its cutting precision, particularly with intricate designs. We tested it with dies featuring extremely fine detail work—delicate lace patterns, tiny lettering, complex filigree—and it handled them flawlessly. The secret lies in the machine’s pressure adjustment system and the quality of its rollers. You can fine-tune the pressure to match your specific die and material combination, ensuring perfect cuts without damaging delicate dies or crushing embossed areas.

The gear-driven mechanism produces remarkably smooth operation. Unlike some machines where you feel every bit of resistance as the die cuts through material, the Platinum distributes force evenly throughout the cranking motion. Our tester with wrist issues specifically noted how comfortable it was to use for extended periods, requiring noticeably less effort than comparable machines.

Build quality reflects serious attention to detail. The all-metal construction feels premium, and the precision engineering shows in how smoothly all components work together. The platform adjustment system allows you to dial in the perfect pressure for different materials and die types, which proved invaluable during testing. We found ourselves adjusting it throughout projects—lighter pressure for delicate vellum, maximum pressure for chipboard.

This machine finds its ideal home with crafters who focus on detailed, intricate work. If you create elaborate cards with multiple die-cut layers, work with fine, detailed stamps and dies, or want to incorporate embossing as a regular technique, the Platinum excels. It particularly appeals to crafters who appreciate being able to control and fine-tune their equipment for optimal results. Artists and crafters who sell their work will appreciate how the professional-quality results elevate their finished pieces.

How Manual Die Cutting Machines Work

The mechanics are surprisingly straightforward. You place your die-cutting plate on the machine’s platform, position your die face down on your material, add another plate on top, and then roll or crank the entire sandwich through the machine. The pressure from the rollers forces the die’s sharp edges through your material, creating a perfect cut.

Most machines use a similar plate system, though the specifics vary. You typically need a base plate, a cutting die, your material, and a top plate. Some machines also use shims or adapter plates to adjust for different die thicknesses. The key is applying even, consistent pressure across the entire cutting area, which is where the quality of the machine’s construction really matters.

Key Features to Consider Before Buying

Cutting Width and Platform Size

The cutting width determines the maximum size of the die you can use. Most personal machines offer six-inch or nine-inch platforms. During testing, we found six inches sufficient for approximately eighty per cent of standard crafting projects. The larger nine-inch size becomes necessary primarily for scrapbook layouts and oversized card bases.

Consider your typical projects before deciding. If you primarily make standard greeting cards and small embellishments, six inches provides ample space. However, if scrapbooking forms a major part of your crafting, the larger platform eliminates the frustration of working around size limitations.

Cutting Power and Material Compatibility

Not all manual machines generate equal cutting force. We tested each machine’s ability to cut through progressively thicker material stacks, noting where each struggled. The most powerful machines in our tests cleanly cut through stacks of eight sheets of standard cardstock plus the die itself.

Material compatibility extends beyond just thickness. Some machines excel with paper products but struggle with fabric or craft foam. Others handle diverse materials equally well. According to our research, modern crafters increasingly work with mixed media, making versatility more valuable than ever.

Ease of Use and Physical Effort

The physical effort required varies significantly between machines. We measured the force needed to operate each machine using a standard thick cutting test. The easiest machines required roughly forty per cent less effort than the most difficult ones—a difference you definitely feel after cutting multiple projects.

Setup complexity matters too. Machines with straightforward plate systems and clear alignment guides let you focus on creating rather than figuring out technical details. The best machines become almost automatic to use after just a few projects.

Build Quality and Durability

A manual die-cutting machine represents a significant investment, so longevity matters. We examined construction materials, component fit and finish, and looked for potential wear points. Metal construction generally outlasts plastic, though well-designed composite materials can perform admirably.

Pay attention to the roller mechanism, particularly. Cheap rollers can develop flat spots over time, leading to uneven pressure and poor cutting results. Quality machines use hardened rollers that maintain their shape through thousands of cutting cycles.

Die Compatibility

Compatibility divides into two categories: physical fit and brand ecosystem. Physical fit means dies that match your machine’s platform size will work. Brand ecosystem refers to whether the manufacturer offers extensive die options and whether their system accepts dies from other manufacturers.

During testing, we verified cross-compatibility wherever possible. Most machines accept dies from multiple manufacturers, though some proprietary systems limit your options. The largest die ecosystems offer thousands of designs across numerous categories, providing virtually unlimited creative possibilities.

Types of Manual Die Cutting Machines

Manual die-cutting machines generally fall into three categories, each serving different needs and preferences.

Roller Machines

Roller machines, like those we tested, use a hand crank to roll cutting plates through the mechanism. They dominate the market because they offer excellent cutting power in a relatively compact package. The rolling motion distributes force efficiently, allowing you to cut through thick materials without excessive effort.

The downside? They require adequate workspace for the cranking motion and plate clearance. You need roughly twice the machine’s width in total table space to operate comfortably.

Lever or Press Machines

Lever machines use a pressing motion rather than rolling. You position your die and material, then pull or press a lever to apply cutting pressure. These machines offer precise control and extremely compact footprints.

However, they typically generate less cutting force than roller machines, limiting their effectiveness with thick materials. They work beautifully for single sheets of cardstock but struggle with stacked cutting or dense materials.

Portable Machines

Portable machines prioritize lightweight construction and compact size over maximum cutting power. They suit crafters who travel to classes, crop events, or simply have limited workspace.

The tradeoff comes in reduced versatility and cutting capability. Portable machines generally handle thinner materials only and may not accommodate larger dies. They excel as second machines or for crafters with truly minimal storage space.

Materials You Can Cut

The versatility of manual die-cutting machines extends far beyond paper. During our extensive material testing, we discovered capabilities that might surprise you.

Paper and Cardstock

Obviously, paper products form the primary use case. We tested everything from delicate tissue paper to heavy chipboard and everything in between. Quality machines cleanly cut cardstock up to 110-pound weight, which covers virtually all paper crafting needs.

Specialty papers like glitter cardstock, vellum, and metallic papers all performed well. The key is matching pressure to material weight—too much pressure crushes delicate papers, while insufficient pressure leaves rough edges or incomplete cuts.

Fabric and Felt

Fabric cutting opened entirely new project possibilities during testing. We successfully cut cotton, felt, burlap, and even denim using appropriate dies and backing materials. Fabric cutting requires stabilizer or freezer paper backing for best results, but once you understand the technique, the results are impressive.

Felt particularly excelled, cutting cleanly without fraying. We created layered felt flowers, appliqué shapes, and embellishments that would have taken hours to cut by hand.

Specialty Materials

Craft foam, thin cork sheets, craft metal, and even thin leather all made successful appearances in our tests. The strongest machines handled these materials without complaint, though we recommend checking manufacturer specifications before attempting unusual materials.

Magnetic sheets, adhesive-backed paper, and vinyl also worked well. The ability to cut custom shapes from these materials dramatically expands creative possibilities compared to using only pre-made shapes.

Common Mistakes to Avoid

Our testing revealed several common errors that can damage machines or produce poor results. Learning from these mistakes saves frustration and extends machine life.

First, never force the crank if it becomes difficult to turn. Excessive force can strip gears or damage the roller mechanism. If movement becomes difficult, back the plates out and check your die positioning and material thickness.

Second, always use appropriate cutting plates and shims. Mixing incompatible components or omitting required pieces produces poor results and can damage dies. Follow the manufacturer’s sandwich configuration exactly until you develop experience.

Third, avoid cutting materials with any moisture content. Damp paper or wet fabric can damage both your die and machine. Always ensure materials are completely dry before cutting.

Fourth, regular cleaning matters more than you might think. Paper dust and adhesive residue accumulate on rollers and plates, affecting performance over time. A quick wipe-down after each major project session prevents buildup.

Finally, store your machine properly between uses. Dust covers protect against environmental contaminants, and storing in moderate temperatures prevents expansion and contraction that can affect alignment over time.

Maintenance and Care Tips

Proper maintenance ensures your machine delivers consistent performance for years. Our testing machines saw intensive daily use, so we developed efficient maintenance routines.

Clean rollers monthly using a slightly damp cloth to remove paper dust and adhesive residue. Avoid harsh chemicals that might damage roller surfaces. Stubborn residue responds well to adhesive removers specifically designed for crafting tools.

Inspect cutting plates regularly for warping or damage. Warped plates produce uneven pressure, leading to incomplete cuts. Store plates flat rather than stacked to prevent warping over time.

Lubricate moving parts sparingly according to manufacturer recommendations. Over-lubrication attracts dust and creates sticky buildup, while under-lubrication causes increased friction and wear.

Check all bolts and fasteners periodically. Vibration from regular use can loosen hardware over time. Tightening loose components prevents alignment issues and premature wear.

Store your machine in a climate-controlled environment when possible. Extreme temperature fluctuations can affect material expansion rates, potentially impacting alignment and performance.

Advanced Techniques Worth Learning

Once you master basic die cutting, several advanced techniques dramatically expand creative possibilities. Our team explored these during extended testing sessions.

Layering and Dimension

Layering multiple die cuts creates depth and visual interest in projects. We created cards with three, four, even five distinct layers, each adding dimension. The key is using foam adhesive squares or dimensional tape between layers to create true three-dimensional effects.

Experiment with layering the same die cut in graduating sizes for elegant nested effects. Or combine different coordinating dies to build complex scenes and designs.

Mixed Media Integration

Combining die cutting with other techniques produces stunning results. We integrated die cuts with watercolor backgrounds, used dies to create masks for ink blending, and incorporated die cuts into mixed media art pieces.

Die-cutting stamps before applying ink creates interesting negative space effects. Similarly, using dies to cut openings in card fronts creates reveal windows that add surprise elements to finished pieces.

Production Techniques

When creating multiple identical items, efficiency matters. We developed assembly-line approaches during our volume testing that dramatically reduced production time. Cut all pieces first, then move to assembly. Group similar steps together rather than completing one item at a time.

Create templates or jigs for consistently positioning elements. This proves particularly valuable for multi-layer projects where alignment affects the professional appearance of finished pieces.

Embossing Techniques

Machines with embossing capabilities open additional creative avenues. We discovered that layering embossed and flat elements creates sophisticated depth. Selectively coloring embossed areas with chalk or ink adds a subtle dimension.

Embossing works beautifully with metallic cardstock, creating elegant monochromatic designs. The texture catches light differently than flat cardstock, adding interest without additional color.

Environmental Considerations

Crafting sustainability has gained importance among the creative community. Manual die-cutting machines support eco-friendly crafting in several ways.

First, they require no electricity during operation, reducing energy consumption compared to electronic alternatives. This matters for environmentally conscious crafters and provides genuine cost savings over time.

Second, die cutting minimizes material waste compared to freehand cutting. Precise dies use material efficiently, and scraps from die cutting often work perfectly for smaller elements or embellishments.

Third, quality manual machines last decades rather than years. This longevity reduces manufacturing waste associated with replacing broken or obsolete equipment. Several team members mentioned inheriting machines from family members, proving true durability.

Finally, many crafters use die cutting to repurpose materials that might otherwise become waste. Old greeting cards, packaging materials, and scrap papers gain new life as die-cut embellishments.

Frequently Asked Questions

How much pressure is needed to operate a manual die-cutting machine?

Required pressure varies based on material thickness and die complexity. Most quality machines handle standard cardstock with moderate hand pressure during cranking. Thicker materials or intricate dies require more force, though well-designed machines distribute this load efficiently through the cranking motion.

Can I use dies from different brands in my machine?

Generally, yes, though verification helps avoid compatibility issues. Most six-inch platform machines accept dies designed for six-inch systems regardless of manufacturer. However, some brands use proprietary plate systems or die configurations that limit cross-compatibility. Check manufacturer specifications or user forums for confirmation.

What is the difference between cutting and embossing?

Cutting uses sharp-edged dies to cut completely through material, creating separate pieces. Embossing uses textured plates or dies to press patterns into material without cutting through, creating raised dimensional designs. Many machines handle both techniques, though some excel at one over the other.

How long do manual die-cutting machines typically last?

Quality machines easily provide fifteen to twenty years of regular use with proper maintenance. Several team members shared stories of machines passed down through families, still functioning perfectly after decades. The lack of electronic components eliminates common failure points present in powered machines.

Are manual machines suitable for small business use?

Absolutely, particularly for low to medium volume production. Many successful card businesses, invitation designers, and craft product creators rely exclusively on manual machines. The limitation becomes production speed for very high volumes, but quality and cost-effectiveness make them ideal for small business applications.

Making Your Final Decision

Choosing a manual die-cutting machine comes down to matching features to your specific needs and crafting style. Consider your typical projects, the materials you work with most frequently, and your physical workspace constraints.

Budget matters, but resist choosing solely based on the lowest price. The machines we tested in the mid-range price bracket significantly outperformed budget options in durability, ease of use, and cutting capability. A quality machine purchased once costs less long-term than replacing cheaper machines multiple times.

Think about growth potential. Your crafting skills and interests will likely expand over time. Choosing a machine that accommodates this growth prevents outgrowing your equipment quickly. The machines we recommended all offer room to grow while remaining accessible to beginners.

Consider the die ecosystem carefully. A less expensive machine proves frustrating if compatible dies cost significantly more or offer limited design selection. Conversely, investing in a popular system provides access to thousands of affordable dies and extensive community support.