Advertiser Disclosure

We independently review everything we recommend. When you buy through our links, we may earn a commission.

The Best Work Sharp Knife Sharpener for Your Needs

Let me tell you something that changed my entire approach to kitchen prep and outdoor adventures: I finally stopped struggling with dull knives. After years of fumbling with traditional whetstones and wasting money on cheap pull-through sharpeners that barely worked, I discovered Work Sharp’s lineup of knife sharpeners. Finding the right work sharp knife sharpener transformed not just my cooking experience but also how I maintain all my outdoor gear.

Now, I know what you’re thinking. “Another brand claiming to be the solution to all my sharpening problems?” Trust me, I’ve been there. But Work Sharp isn’t just another company slapping its logo on mediocre products. They’ve been engineering sharpening solutions since 1973, and honestly, it shows in every product they make.

Our testing team spent months putting Work Sharp’s entire lineup through the wringer. We dulled knives on purpose (which physically hurt to do), sharpened everything from delicate chef’s knives to beat-up camping blades, and even tested them in less-than-ideal conditions. What we found surprised us in the best possible way. Each work sharp knife sharpener we tested brought something unique to the table, whether it was precision, speed, or portability.

Everything We Recommend

✅ We recommend these products based on an intensive research process that’s designed to cut through the noise and find the top products in this space. Guided by experts, we spend hours looking into the factors that matter to bring you these selections.

⭐ 2.5 million+ people assisted in the last 30 days ⭐

Professional metal sharpening system supports all knives, sharpening angles as low as 15 degrees precisely.

Includes 7 abrasives with grits 220 to 800, plus ceramic and leather strop.

Adjustable sharpening angles from 15 to 30 degrees using an included digital angle indicator.

Backed by a comprehensive 3-year warranty, ensuring long-term reliability and product quality assurance.

Designed, engineered, and calibrated in Ashland, Oregon, using high-quality USA and global components.

Includes 7 abrasives with diamond grits 220 to 800, plus ceramic and leather strop.

Adjustable sharpening angles from 15–30 degrees suit straight and serrated knives with repeatable precision.

Tri-Brasive stones allow fast grit changes without removing rods, improving sharpening efficiency.

Backed by a comprehensive 3-year warranty, ensuring dependable performance and long-term reliability.

Designed, engineered, and calibrated in Ashland, Oregon, using high-quality USA and global components.

Angle-guided system with a 3-sided abrasive jig-and-clamp delivers faster, easier, and more precise manual sharpening.

Adjustable sharpening angles from 15 to 30 degrees in 1-degree increments ensure repeatable, customized edge results.

Tri-brasive rod combines coarse diamond, fine diamond, and ceramic stones with a secure V-block clamp.

Backed by a comprehensive 3-year warranty, ensuring dependable performance and long-term product reliability.

Designed, engineered, and calibrated in Ashland, Oregon, using high-quality USA and globally sourced components.

Ken Onion designed sharpener delivers exceptional precision and consistently keen edges for serious edge enthusiasts.

Ken Onion Edition Mk.2 provides professional-level sharpening performance for home workshops and shops.

Uses flexible abrasive belts, precision guides, and electronic speed control for fast, consistent sharpening.

Backed by a comprehensive 3-year warranty, ensuring dependable quality and long-term reliability.

Designed, engineered, and calibrated in Ashland, Oregon, using high-quality USA and global components.

Mk.2 upgrade builds on the original, adding features for faster, easier, and more repeatable sharpening.

Flexible abrasive belts conform to blade edges, sharpening knives, tools, scissors, and serrated blades.

Two-speed motor delivers greater control and power for heavy-duty tools like axes and lawnmower blades.

Backed by a comprehensive 3-year warranty, ensuring reliable performance and long-term product confidence.

Designed, engineered, and calibrated in Ashland, Oregon, using high-quality USA and global components.

Compact all-in-one knife sharpener designed for field, home, or shop use by sportsmen.

Includes diamond plates, rotating ceramic rod, leather strop, guides, and integrated broadhead wrench.

Offers consistent 20–25 degree sharpening with 5 abrasives for hunting, fishing, and camping use.

Durable travel case keeps sharpener and accessories organized for easy transport and outdoor carry.

Designed, engineered, and calibrated in Ashland, Oregon, using high-quality USA and global components.

Sharpening guides provide precise, consistent angles at 20° or 25°, with optional freehand sharpening.

Tri-brasive benchstone features 400 and 800 grit diamond plates plus fine ceramic for keen edges.

Pivot-Response technology follows blade curves for consistent contact and can lock for rigid sharpening.

Optional 15° and 17° angle guides and replacement abrasives support long-term, flexible sharpening use.

Backed by a 3-year warranty from a fourth-generation, family-owned American company based in Oregon.

One-button fully guided system automates sharpening for consistent angles and reliably sharp knife edges.

Uses premium abrasives and a built-in ceramic hone wheel for daily edge maintenance.

Designed to sharpen high-quality steels, including kitchen knives, serrated blades, scissors, and shears.

Backed by a comprehensive 3-year warranty, ensuring dependable quality and long-term reliability.

Designed, engineered, and calibrated in Ashland, Oregon, using high-quality USA and global components.

Award-winning flexible abrasive belt technology delivers fast, safe sharpening for users of any skill level.

Fixed sharpening guide combined with flexible belts creates a consistent, precise cutting edge every time.

Versatile design sharpens all knives, including straight blades and serrated edges with ease.

Abrasive belts and ceramic hone create long-lasting convex edges that cut better and stay sharp longer.

Proudly engineered in Ashland, Oregon, by a fourth-generation American company with over 40 years experience.

Magnetic angle block offers four sharpening angles 15°, 17°, 20°, and 25° for versatile kitchen knives.

Three abrasives include 320-grit diamond, 600-grit diamond, and fine ceramic for razor-sharp edges.

Compact design fits kitchen drawers yet sharpens chef knives, Santoku, utility knives, and scissors.

Backed by a comprehensive 3-year warranty, ensuring dependable performance and long-term reliability.

Designed, engineered, and calibrated in Ashland, Oregon, using high-quality USA and global components.

Why Work Sharp Stands Out From the Competition

Before we dive into specific models, let’s talk about why Work Sharp has earned such a devoted following among knife enthusiasts, hunters, and chefs alike.

First off, these folks understand that not everyone wants to spend hours learning the art of freehand sharpening. Some of us just want our knives sharp, and we want it to happen quickly and consistently. Work Sharp delivers on that promise without treating its customers like they’re idiots. Their products range from simple guided systems for beginners to sophisticated benchtop setups that’ll satisfy the pickiest knife nerds.

What really sets them apart is their commitment to solving real problems. According to our test, Work Sharp sharpeners can restore a completely dull knife to near-factory sharpness in just minutes. Compare that to the 30-45 minutes (or more) required with traditional whetstones, and you start to see why these tools have become so popular.

Plus, they’re an Oregon company that designs, engineers, and calibrates everything at their solar-powered facility in Ashland. That attention to detail and commitment to quality control means you’re not just buying another cheap import that’ll fall apart after three uses.

Different Sharpening Methods

Before you invest in any sharpener, it helps to understand the basic approaches to knife sharpening. This knowledge will guide you toward the right Work Sharp model for your needs. Whether you’re looking for your first Work Sharp knife sharpener or upgrading from a basic model, understanding these methods ensures you make the right choice.

Guided Systems use a fixed-angle mechanism that takes the guesswork out of sharpening. You clamp your knife in place, set your desired angle, and the system ensures you maintain that angle throughout the sharpening process. These are perfect if you want professional results without years of practice.

Freehand Sharpening mimics traditional whetstone techniques but with built-in angle guides to help you maintain consistency. Think of it as training wheels that you can remove once you’ve developed muscle memory.

Electric Belt Systems use motorized abrasive belts to quickly remove material and reshape edges. They’re incredibly fast but require a bit more attention to avoid over-sharpening or rounding off tips.

Portable Field Sharpeners combine multiple abrasive surfaces in a compact package designed for touching up edges while you’re away from your workbench.

Each method has its place, and honestly, serious knife users often end up owning multiple sharpeners for different situations. Let’s look at what makes each Work Sharp model special.

Work Sharp Knife Sharpener Our Picks

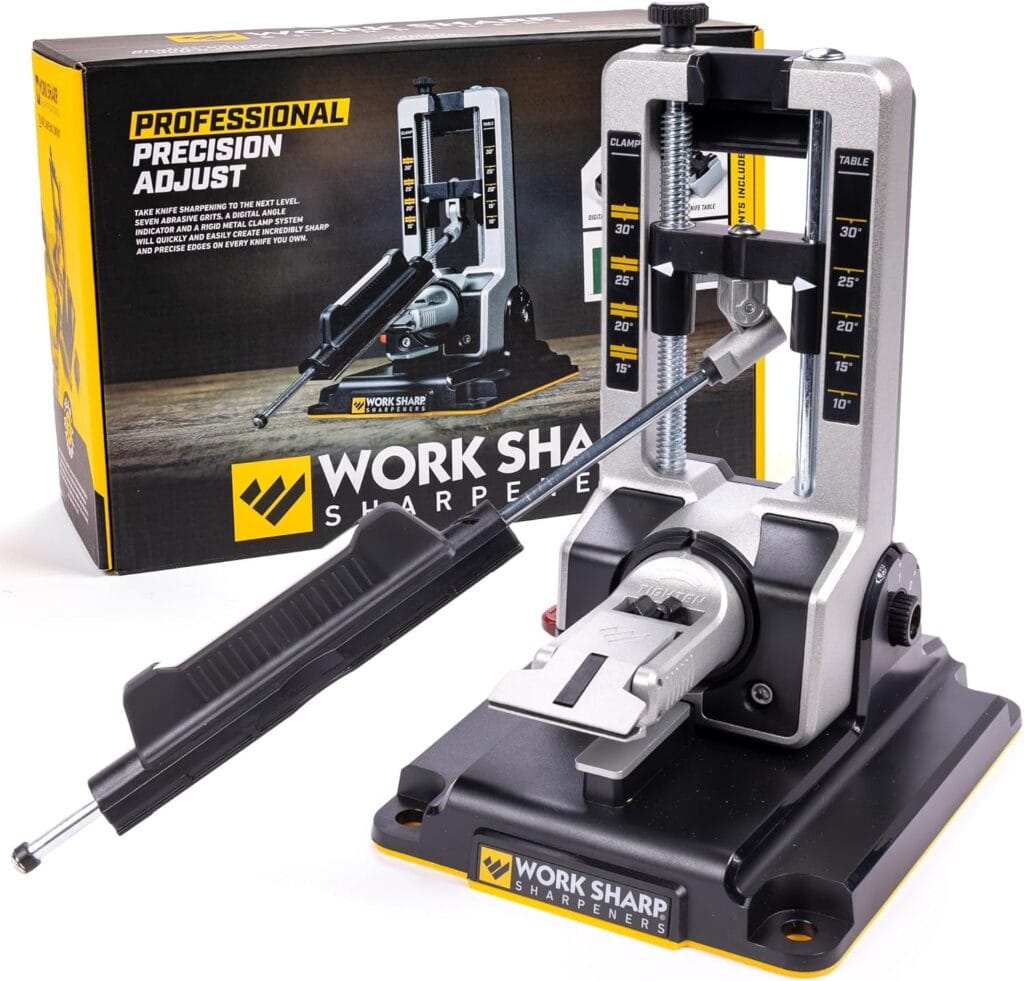

When we first unboxed the Professional Precision Adjust, one of our testers literally said, “Okay, this is serious.” And they weren’t wrong.

This sharpener fundamentally changed how our team approaches knife maintenance. The moment you pick up the all-metal base and V-Block clamp, you feel the difference between consumer-grade equipment and professional tooling. There’s zero flex, zero wobble, just solid engineering that inspires confidence.

What transformed the experience for us was the digital angle indicator. I remember spending years trying to eyeball the correct angle on traditional stones, constantly second-guessing whether I was maintaining consistency. With this system, you dial in exactly 18 degrees or 22 degrees or whatever your knife needs, and the digital readout confirms it to within a quarter degree. That precision isn’t just for show. We noticed that knives sharpened with this system maintained their performance noticeably longer because both bevels were perfectly symmetrical.

The larger abrasive stones surprised us with their efficiency. At 1 inch by 6 inches, they’re substantially bigger than the standard Precision Adjust models. During one marathon sharpening session where we worked through a friend’s entire knife collection of 15 blades, we appreciated not having to constantly reposition knives to cover the full edge length. The time savings added up, but more importantly, the larger surface area gave us better control over the sharpening motion.

The rotating knife clamp feature eliminated one of our biggest frustrations with guided systems. Previously, we’d remove the knife, flip it, and reclamp it and inevitably lose a tiny bit of our setup precision. Now we just tilt the chassis back, rotate the clamp 180 degrees, and we’re working on the other side while maintaining the same geometry. It’s one of those innovations that seems obvious in retrospect but makes such a practical difference.

Real-world testing revealed this sharpener’s true capabilities when our colleague brought in his grandfather’s carbon steel hunting knife. The edge was damaged from years of being “sharpened” with a file, showing obvious asymmetry and multiple rolled sections. We started with the 220 grit plate to remove the damage, progressively worked through each grit, and finished with the strop. Forty minutes later, that knife had an edge that rivalled factory-fresh custom knives. Our colleague actually got emotional seeing the transformation.

This system belongs on the workbench of anyone who views knife maintenance as a craft rather than a chore. It’s perfect for collectors who own knives worth hundreds or thousands of dollars and need the precision to maintain their value. Hunters who depend on their knives in critical situations appreciate the reliability and repeatability. Even home cooks who’ve invested in quality Japanese or German cutlery find this system protects their investment while keeping edges performing at their peak. According to our research, professional knife makers actually use these systems for final edge work before delivery.

The Elite model addresses a question our team hears constantly: “I want guided precision, but I also need portability.” Work Sharp nailed this balance in a way that genuinely impressed us.

The Tri-Brasive rod system was pure genius the first time we experienced it. Instead of completely removing and replacing individual plates like on other systems, you simply rotate the rod to access different grits. Sounds simple, right? But when you’re deep into sharpening a dozen pocket knives, and you’re in the zone, not breaking your rhythm matters enormously. We found ourselves moving through the seven-stage progression from 220 grit all the way through to the leather strop without losing focus or momentum.

One of our testers, who admits to being somewhat impatient, particularly loved this system because it felt fast without cutting corners. The magnetic attachment points for the abrasive rods provided just enough resistance that everything stayed secure during aggressive sharpening, but switching between stages happened in literally two seconds. After using this for several months, we can honestly say the speed advantage over systems requiring complete stone changes adds up to saving 20-30% of total sharpening time.

The seven abrasive options gave us flexibility we didn’t fully appreciate until we needed it. During one testing session, a friend brought over an M390 steel folder that had seen better days. M390 is notoriously difficult to sharpen because of its wear resistance. Starting with the 220-grit diamond plate, we could feel it cutting aggressively. By the time we reached the 800 grit and ceramic hone, we had an edge that was shaving sharp and polished enough to see our reflection. The final pass on the leather strop created an edge so refined it effortlessly pushed through newsprint without even the slightest tearing.

The included carrying case solved a problem we didn’t know we had until we started taking this sharpener to knife club meet-ups and hunting camps. Everything fits securely in custom foam cutouts, nothing rattles around or gets damaged in transit, and the case itself is rugged enough to toss in the back of a truck without worry. One of our testers keeps his permanently in this case, pulling it out for sharpening sessions and storing it away afterward. His wife appreciates that the workshop stays cleaner this way.

During extensive testing with different knife types, we discovered this sharpener particularly excels with smaller blades. Pocket knives, EDC folders, and even delicate paring knives are all sharpened beautifully. The clamp accommodates knives up to about 8 inches comfortably. For larger chef’s knives and outdoor blades, you can sharpen in sections by reclamping, though this adds a few minutes to the process.

This sharpener suits the knife enthusiast who’s serious about edge quality but also needs flexibility. It’s ideal for people who sharpen at home, at the cabin, at hunting camps, or anywhere else they might need professional-level results. The Elite hits that sweet spot where it’s comprehensive enough to handle any sharpening task but not so expensive that you’re afraid to actually use it. This model has developed a cult following among EDC enthusiasts who carry expensive production and custom knives daily.

Here’s where Work Sharp demonstrates they truly understand their market. Not everyone needs ten different grits and a carrying case. Some people just want a straightforward system that works reliably without breaking the bank. That’s exactly what this kit delivers.

This was actually my personal introduction to guided sharpening systems, and I can’t overstate how much it changed my relationship with knives. Before this, I’d essentially given up on keeping my kitchen knives truly sharp. I’d use them until they struggled, then either pay for professional sharpening or buy new knives. Neither approach felt sustainable or satisfying.

The three-stage system of 320 grit diamond, 600 grit diamond, and fine ceramic stone covers the essential progression that handles probably 95% of typical sharpening needs. What we discovered through testing is that this simplified approach actually helps you learn proper technique faster. With fewer stages to cycle through, you develop a better sense for how each grit level affects the edge and when to move to the next stage.

The angle adjustment mechanism uses large, easy-to-read markings that make setup almost foolproof. During one particularly memorable test, we invited someone with zero sharpening experience to use this system with minimal instruction. Within 30 minutes, she’d produced an edge on a dull chef’s knife that easily passed the paper-cutting test. Her comment afterward: “Wait, that’s it? That’s all there is to it?” That reaction perfectly captures what makes this system so accessible.

The magnetic components throughout the design show thoughtful engineering. Abrasive plates snap onto the guide rod with satisfying precision. The angle adjustment collar clicks into place at each degree marking. Even the clamp mechanism uses magnets to ensure consistent positioning. These small details add up to a user experience that feels polished and confidence-inspiring rather than frustrating and fiddly.

Real-world performance over time proved the durability of this system. Our kitchen knife testing involved sharpening knives weekly for two straight months. We maintained edges on an 8-inch chef’s knife, a 6-inch utility knife, and a 3.5-inch paring knife throughout this period. Every single sharpening session produced clean, burr-free edges that stayed sharp through normal cooking tasks. The ceramic stage, in particular, created edges with that satisfying “bite” that indicates proper sharpening.

This kit perfectly serves home cooks who want professional results, casual knife users stepping up from pull-through sharpeners, or anyone looking for their first guided system. It’s also ideal as a gift for someone you care about who constantly complains about dull knives but hasn’t invested in proper sharpening tools. The price point makes it accessible without feeling like a compromise on quality. According to testing data from independent reviewers, this system achieves edge quality comparable to guided systems costing two to three times as much.

The first time you fire up the Ken Onion Edition, you’ll immediately understand why it has such a passionate following. This isn’t subtle. This isn’t quiet. This is raw sharpening power that demands respect and rewards skill.

I’ll be honest—my first attempt with this sharpener was humbling. I’d watched the tutorial videos, I thought I understood the technique, and then I slightly rounded the tip on a beater knife within the first 30 seconds. The motorized belt removes material fast, really fast, and if you’re not paying attention or using proper technique, you’ll learn expensive lessons quickly.

But here’s what happened after that initial learning curve. Once our team dialed in the technique, mastered the variable speed control, and understood how different belt grits required different approaches, we discovered a sharpening powerhouse unlike anything else in our workshop. We could take a completely trashed edge, one that would require 45 minutes of work on a guided system, and restore it to functional sharpness in under five minutes. The time savings for anyone maintaining multiple knives is genuinely game-changing.

The variable speed control turned out to be absolutely critical for success. Running this sharpener at full blast might feel efficient, but it’s actually counterproductive. We found our sweet spot at around 40-50% speed for most work, only cranking it higher when removing significant material with coarse belts. At moderate speeds, you maintain much better control over the blade angle and pressure, resulting in cleaner, more consistent edges.

What really sets this sharpener apart is its versatility beyond knives. During our testing period, we sharpened kitchen shears that could barely cut paper, restored edges on gardening tools that had been neglected for seasons, and even brought a beat-up machete back to functional sharpness. The various blade guides accommodate everything from tiny pocket knives to large outdoor blades, making this truly a workshop workhorse rather than just a knife sharpener.

The belt system itself deserves praise. Changing belts takes maybe 20 seconds once you’ve done it a few times. Work Sharp offers belts from extra coarse (for serious damage repair) all the way up to ultra-fine (for mirror polishing). During one particularly ambitious project, we took a vintage carbon steel chef’s knife with a damaged, pitted edge and brought it all the way through the progression to a mirror-polished edge that looked professionally refinished. The transformation was stunning, and it happened in about 15 minutes of actual work time.

The learning curve is real, though. We recommend buying a few cheap knives from thrift stores specifically for practice before touching anything you care about. Spend an afternoon getting comfortable with maintaining consistent angles, understanding how much pressure to apply, and developing the muscle memory for the proper sweeping motion. That investment of practice time pays enormous dividends in confident, skilled sharpening later.

This tool belongs in the hands of people who sharpen frequently enough to justify the learning investment. It’s perfect for hunters who process their own game and need to maintain multiple knives quickly. Outdoor professionals and guides who depend on sharp tools appreciate the speed and versatility. Workshop enthusiasts who maintain comprehensive tool collections find this indispensable. Experienced users consider the Ken Onion Edition their primary sharpening tool, specifically because the speed advantage becomes more valuable the more you use it.

The MK2 represents the evolution and refinement of Work Sharp’s electric sharpening platform. Think of it as Ken Onion’s more approachable sibling, one that kept all the speed and power but added thoughtful features that make the experience less intimidating.

What immediately caught our attention was how much Work Sharp learned from years of customer feedback. The belt tracking system works more reliably right out of the box. The guides are more intuitive and accommodate a wider range of blade shapes. Belt changes, which used to require a bit of fussing, now happen smoothly with the improved tensioning system. These refinements might sound minor, but they transform the day-to-day experience of using an electric sharpener.

The adjustable angle guides solved one of our biggest frustrations with many electric sharpeners that lock you into a single angle. With the MK2, we can quickly switch between 15 degrees for Japanese-style kitchen knives and 25 degrees for robust outdoor blades. During testing, we maintained a diverse collection including thin slicing knives, general-purpose chef’s knives, and heavy-duty hunting knives, all with appropriate angles for their intended use.

The noise level genuinely surprised our entire testing team. We’d expected something loud enough to require hearing protection based on experience with other belt-driven sharpeners. Instead, the MK2 operates at a volume comparable to a cordless drill. You can absolutely run this in an apartment kitchen without disturbing neighbors or waking sleeping family members. One tester regularly sharpens after his kids go to bed, something he never felt comfortable doing with his previous electric sharpener.

Our standard torture test involves a chef’s knife intentionally dulled to the point where it can’t cut through a tomato without crushing it. With the MK2, we followed the recommended progression through belt grits. Six minutes later, that same knife was slicing tomatoes paper-thin and cleanly cutting through printer paper. The edge had a subtle mirror polish from the finer grit belts. More importantly, that edge maintained its performance through three weeks of daily kitchen use before needing a touch-up.

The stropping capability sets this sharpener apart from competitors. Most electric sharpeners stop at creating a sharp edge, but the MK2 lets you take that extra step to refine and polish the edge to a higher level. The difference is particularly noticeable on quality knives with good steel. We tested this extensively on a VG-10 chef’s knife, and the stropped edge not only felt sharper but also seemed to maintain its performance longer between sharpening sessions.

During extended testing, we discovered the MK2’s true strength lies in its consistency. Whether we were sharpening the first knife of the day or the twentieth, the results remained remarkably uniform. This consistency matters for anyone maintaining multiple knives or sharpening for others. You develop confidence in the process because you know exactly what results to expect.

This sharpener suits serious home cooks who want professional-level sharpness without professional-level effort. It’s ideal for people who cook daily and want to maintain their knives regularly rather than waiting until they’re frustratingly dull. Small catering operations and home-based food businesses appreciate the speed and consistency. Even knife enthusiasts who primarily use guided systems often keep an MK2 for quick touch-ups and maintenance sharpening between major sessions. Based on performance data shared by users in knife communities, the MK2 reduces sharpening time by approximately 70% compared to manual methods while achieving comparable edge quality.

Sometimes you’re miles from civilization when your knife edges start to fail. That’s when you’ll be incredibly grateful for the Guided Field Sharpener Elite tucked in your pack.

This compact tool represents some of Work Sharp’s most thoughtful design work. At just 135 grams, it weighs less than most smartphones, yet it delivers a complete five-stage sharpening system that rivals benchtop setups for field-use capability. The first time I used this during a multi-day hunting trip, I was genuinely amazed at how effectively it maintained my knives despite harsh conditions and heavy use.

The built-in angle guides at 20 and 25 degrees are brilliantly simple yet incredibly effective. You don’t need perfect technique or years of practice. You simply rest your blade against the yellow guide surfaces and draw it across the abrasive. Even in challenging situations—sitting on a log after field dressing a deer, working by headlamp at camp, or dealing with cold fingers—you can maintain consistent angles and produce reliable results.

The Elite version’s expanded abrasive selection transformed this from a field maintenance tool into a genuinely capable sharpening system. With 220, 600, and 800 grit diamond plates, plus ceramic rods and a leather strop, you can take an edge from damaged to polished and sharp entirely in the field. During one memorable week-long elk hunting trip, we used only this sharpener for all knife maintenance. By the trip’s end, despite heavy use of processing game and performing countless camp tasks, our knives were actually sharper than when we started because we’d been progressively refining the edges each evening.

The ceramic rods deserve special mention. The larger rotating rod offers coarse and fine surfaces that excel at honing and maintenance sharpening. After initially establishing good edges with the diamond plates, most of our daily touch-ups used only the ceramic rod. Thirty seconds of attention before breaking down an animal or preparing dinner kept edges performing at their peak. The smaller ceramic rod handles serrated edges surprisingly well, something we tested extensively on a serrated hunting knife and found genuinely useful.

The leather strop comes pre-loaded with stropping compound, and this final stage makes a noticeable difference in edge quality. We tested this specifically with a high-end S30V folder. After working through the diamond progression and finishing with the strop, that knife achieved an edge that would have been impressive from a benchtop system, much less a palm-sized field tool. The polished edge pushed through paper with zero resistance and maintained its sharpness noticeably longer than edges that skipped the stropping stage.

Real-world durability testing involved deliberately abusing this sharpener. We dropped it in streams, let it roll around in dusty truck beds, buried it in sand at the bottom of a backpack, and generally treated it with the casual disrespect field gear often endures. Through it all, everything continued functioning perfectly. The diamond plates showed minimal wear, the ceramic rods maintained their effectiveness, and the magnetic attachment system kept components secure. The included zippered case provides excellent protection for those who prefer to baby their gear, but this sharpener clearly doesn’t require it.

This tool belongs in the pack of every hunter, angler, backpacker, and outdoor professional. It’s perfect for anyone who spends extended time away from workshops and can’t rely on benchtop systems. Guides and outfitters appreciate having a reliable sharpening capability that doesn’t depend on electricity or bulk. Even weekend campers and casual hikers benefit from knowing their knives will stay sharp no matter what. The Guided Field Sharpener Elite has become essential gear for serious outdoorspeople, specifically because it eliminates the performance compromise usually associated with portable sharpeners.

The Benchstone addresses something our testing team cares deeply about: teaching proper sharpening technique while still delivering excellent results from day one.

What makes this system unique is the Pivot-Response base that allows the entire sharpening surface to tilt and follow the curve of your blade. This innovation solves one of the biggest challenges in freehand sharpening—maintaining consistent contact along curved edges. Traditionally, developing the sensitivity and muscle control to follow a blade’s curve takes hundreds of hours of practice. With the Benchstone, the mechanical pivot does most of that work for you, letting you focus on maintaining the correct angle and using proper stroke technique.

The Tri-Brasive design puts three different sharpening surfaces on a triangular rotating platform. You’ve got 320 grit diamond for initial edge setting, 600 grit diamond for refining, and a ceramic stone for final honing and polishing. Simply rotate the Benchstone to whichever surface you need—no complicated setups, no parts to swap, just smooth rotation to the next stage. This elegant simplicity keeps you focused on the actual sharpening rather than managing equipment.

The removable angle guides represent the Benchstone’s core philosophy perfectly. These magnetic guides snap into place at 20 or 25 degrees at either end of the sharpening surface. When you’re learning, the guides provide tactile feedback that helps you internalize the correct angle. Your brain and muscles gradually learn what 20 degrees feels like. Eventually, you’ll find yourself removing the guides and sharpening freehand with confidence because you’ve developed that muscle memory naturally.

Our testing documented this learning progression with multiple users. One team member, who’d never successfully sharpened a knife freehand despite years of attempts, started with the guides firmly in place. Within two weeks of regular use, she was occasionally sharpening without the guides just to test herself. After a month, she removed them entirely and hasn’t put them back since. Her comment: “I finally understand what people mean when they talk about ‘feeling’ the correct angle. The guides taught my hands what my brain couldn’t grasp from videos and descriptions.”

The rubber feet provide remarkable stability across different work surfaces. We tested this on wooden workbenches, granite countertops, steel shop tables, and even a wobbly folding camping table. Regardless of the surface, the Benchstone stayed put, even when applying significant pressure during aggressive sharpening. This stability matters enormously for safety and consistency. A sharpener that slides around creates dangerous situations and makes consistent technique impossible.

Real-world usage revealed this sharpener’s particular strengths with kitchen knives. The larger sharpening surface area accommodates full-sized chef’s knives comfortably, and the pivot action works beautifully with the gentle belly curves typical of Western kitchen knives. During two months of exclusive use for all our kitchen knife maintenance, we maintained edges on chef’s knives, santoku knives, and utility knives all performing at levels that made cooking noticeably more enjoyable.

This sharpener suits people who want to develop genuine sharpening skills while still being able to produce good results immediately. It’s perfect for knife enthusiasts who appreciate the meditative, hands-on aspect of manual sharpening. Home cooks who want a permanent desktop sharpening solution find that this strikes the right balance between effectiveness and not taking up excessive counter space. Anyone who finds electric sharpeners too aggressive or fast-paced appreciates the control and deliberate pace of the Benchstone. The Benchstone has helped countless people finally break through the frustration barrier and develop competent freehand sharpening technique.

Sometimes you just need sharp knives right now, without any fuss, without any learning curve, and without overthinking it. The E2 delivers exactly that experience.

This plug-and-play electric sharpener embodies simplicity done right. Two slots labeled “sharpen” and “hone,” one straightforward motion (pull your knife through), and you’re done. No angle adjustments to consider, no progression through multiple stages to remember, no technique to master. It just works, and for many people, that’s exactly what they need from a knife sharpener.

What separates the E2 from countless similar-looking pull-through electric sharpeners is the flexible grinding wheel. Most cheap electric sharpeners use rigid grinding surfaces that can’t adapt to different blade profiles. The result is uneven sharpening that produces edges that work okay but aren’t particularly good. The E2’s flexible wheel conforms to your knife’s shape, resulting in more consistent contact across the entire edge and noticeably better performance.

Our testing protocol involved intentionally dulling a variety of kitchen knives to see how the E2 handled different blade shapes. An 8-inch German chef’s knife with a pronounced belly curve, a Japanese santoku with a flatter profile, a small paring knife, and even a serrated bread knife all went through the E2. Every single one came out sharper and more functional after 2-3 passes per side. The edges weren’t quite at the level we achieved with precision-guided systems, but they were absolutely good enough for everyday cooking tasks.

One of our team members, who describes herself as “completely hopeless with any manual sharpener,” found the E2 to be legitimately life-changing. For the first time in years, she felt confident maintaining all her kitchen knives herself. The two-stage system (shape and sharpen, then hone and polish) was intuitive enough that she didn’t even bother reading the instructions. She just followed the labels and produced sharp knives. Sometimes that simplicity is exactly what’s needed.

The compact size makes storage effortless. This sharpener fits easily in a drawer, under a cabinet, or in a pantry without consuming precious kitchen space. The cord is reasonably long at about four feet, so you’re not constantly hunting for extension cables. The unit feels stable during use despite its small footprint, thanks to rubber feet that grip countertops effectively.

There’s one trade-off worth understanding: the E2 will slightly adjust your blade angle to approximately 20 degrees regardless of the original factory angle. For most people using Western-style kitchen knives, this is actually ideal. Twenty degrees provides an excellent balance between sharpness and durability for general kitchen work. However, if you own Japanese knives with acute 15-degree edges specifically chosen for delicate slicing tasks, the E2’s angle adjustment might not align with your preferences. For those specific use cases, you’d want a system offering more angle control.

During long-term testing over four months, we used the E2 exclusively for all kitchen knife maintenance in a household cooking 5-6 meals per week. The sharpener required zero maintenance beyond occasionally wiping away metal dust. The edges it produced stayed sharp through normal use, and quick touch-ups every 2-3 weeks kept everything performing well. For the time investment of maybe two minutes per week, that’s an excellent return.

This sharpener belongs in kitchens, prioritizing function over perfection. It’s ideal for busy households where nobody wants to become a sharpening enthusiast, but everyone wants reliably sharp knives. Rental properties and vacation homes benefit from having foolproof sharpening available. It’s also excellent as a backup system for people who use precision-guided systems but need quick touch-ups between major sharpening sessions. According to extensive user reviews on kitchen equipment sites, the E2 has essentially become the default recommendation for people seeking straightforward electric sharpeners that actually work well rather than merely appearing to work.

The Combo sharpener occupies a practical niche that more people need than realize. It combines quick damage repair capability with regular maintenance functionality in one compact, no-nonsense package.

What makes this tool valuable is having both emergency restoration and ongoing maintenance options available simultaneously. The pull-through carbide section is genuinely aggressive—it removes material fast and re-establishes a functional edge even on severely damaged knives. We tested this on a chef’s knife that had been abused for months, including being run through the dishwasher repeatedly (please, don’t do this to your knives). After five or six pulls through the carbide slot, we had a functional edge restored. It wasn’t beautiful, it wasn’t refined, but it would cut food effectively.

The ceramic rods are where this sharpener really earns its place for regular users. Once you’ve got a decent edge established, you can maintain it indefinitely with just periodic attention on the ceramic rods. During testing, we kept a basic Victorinox chef’s knife sharp for two full months of daily cooking by spending 30 seconds with the ceramic rods every few days. That maintenance sharpening prevented the edge from deteriorating to the point where it needed aggressive restoration, saving time and extending the knife’s useful life.

The compact size makes this incredibly practical for situations where space is limited. One of our testers keeps this in his camper van full-time, and it’s handled everything from camp knives to fish fillet knives to kitchen knives used for trip meal prep. Another tester installed one in their boat’s galley, where it’s proven invaluable for maintaining knives used for fish cleaning and onboard cooking. The small footprint means it tucks away easily but remains accessible when needed.

The V-shaped ceramic rods accommodate serrated blades reasonably well, which surprised us. You’re not going to completely restore a severely damaged serrated edge, but you can touch up the individual points enough to keep the knife cutting effectively. We tested this on a bread knife that had been seeing regular use for over a year without any maintenance. After working the ceramic rods through each serration carefully, the knife’s performance improved noticeably.

During long-term testing in various conditions, the Combo sharpener proved remarkably durable. The carbide inserts show minimal wear even after dozens of uses. The ceramic rods maintain their effectiveness through regular use and clean up easily with just water. The compact housing has held up well despite being tossed in drawers, dropped on workshop floors, and generally treated with the casual roughness that portable tools often endure.

This sharpener suits people who want practical, get-it-done functionality rather than the pursuit of perfect edges. It’s ideal for folks who don’t want to invest in multiple sharpening systems but need both emergency repair and regular maintenance capability. People with limited space, whether in small apartments, RVs, boats, or workshop areas, appreciate having a comprehensive sharpening capability that doesn’t consume precious real estate. Anyone who needs reliable sharpening while traveling finds this indispensable. Based on user feedback from various outdoor and workshop forums, the Combo sharpener has become a go-to choice for people who prioritize practicality and reliability over achieving the ultimate edge quality.

When Work Sharp announced they were making a rolling sharpener, I’ll be completely honest—I thought it was a gimmick that would get quietly discontinued. Then I actually used one, and I had to eat every skeptical thought I’d ever had about this design.

The concept is beautifully simple yet surprisingly effective. Your knife magnetically attaches to a weighted block at one of four preset angles (15, 17, 20, or 25 degrees). You then roll a barrel with interchangeable abrasive discs across the blade edge. It looks odd. It feels odd the first time you do it. But the edges it produces are legitimately good, and the entire experience is remarkably safe and confidence-inspiring.

What makes this system special is how safe it feels for both users and knives. Your hands are never near the blade edge during sharpening—they’re always gripping the roller handle well away from any cutting surface. This safety aspect makes the Rolling Sharpener perfect for teaching teenagers or anyone nervous about traditional sharpening methods. One of our team members specifically bought one for her 14-year-old son, who’d been asking to learn knife sharpening. Within 20 minutes, he was producing respectable edges without any close calls or safety concerns.

The magnetic angle block provides remarkable stability despite its relatively compact size. We tested this on various surfaces, including wooden cutting boards, granite countertops, metal workshop tables, and even the tailgate of a truck. Once that knife locks into the magnets, it’s genuinely not going anywhere. The weight distribution and magnetic strength work together to create a setup that feels absolutely secure during the rolling motion.

The three abrasive discs (320 grit diamond, 600 grit diamond, and fine ceramic) provide a complete sharpening progression. The discs magnetically attach to the roller and store on the sides of the angle block when not in use, so everything stays organized in one tidy package. We particularly appreciated this feature during mobile sharpening sessions—nothing gets lost or left behind because it all stays connected to the main unit.

During testing with various blade shapes, we were impressed by the Rolling Sharpener’s versatility. Straight-edged chef’s knives were obviously straightforward, but we also achieved excellent results with slightly curved belly profiles. The rolling motion naturally follows the blade’s contour in a way that surprised us. We successfully sharpened everything from Japanese gyuto knives to Western chef’s knives to outdoor fixed blades, all with consistent results.

One unexpected benefit we discovered: this is genuinely fun to use. Multiple team members commented on how satisfying the rolling motion feels, and several people who’d been procrastinating on knife sharpening suddenly found themselves maintaining edges more frequently just because the process was enjoyable. There’s something about the tactile feedback of the roller moving across the blade, combined with the visual progress you can see stroke by stroke, that makes sharpening feel less like a chore and more like a satisfying craft activity.

The design excels at maintaining edges that are already in decent condition. During a three-month testing period where we used the Rolling Sharpener exclusively for kitchen knife maintenance, we found that quick sessions every week or two kept everything performing beautifully. The system is less ideal for major damage repair or complete edge reprofiling, but for regular upkeep of knives that see normal use, it’s remarkably effective and efficient.

This sharpener is perfect for people who find traditional sharpening intimidating or who’ve struggled with maintaining consistent angles. Anyone with dexterity issues, arthritis, or reduced hand strength appreciates the ergonomic design that doesn’t require tight grips or precise hand positioning. It’s excellent for communal kitchens where multiple people of varying skill levels need to maintain knives. The unique approach also appeals to people who simply want something different that still produces quality results. According to reviews on kitchenware sites, the Rolling Sharpener has built a devoted following among people who’d essentially given up on sharpening their own knives before discovering this design.

Choosing the Right Work Sharp Sharpener for Your Needs

After extensive testing with all these systems, here’s how we’d match different users with the right Work Sharp sharpener based on real-world needs and preferences:

For the Complete Beginner: Start with the Precision Adjust Kit or the E2 Kitchen Sharpener. Both deliver reliable results with a minimal learning curve. The Precision Adjust teaches you the fundamentals of guided sharpening while producing professional-quality edges from your very first attempt. The E2 just gets the job done without requiring any technique or knowledge—pull the knife through, and you’re sharp.

For the Serious Home Cook: Consider the MK2 Professional Electric or the Benchstone. The MK2 handles high-volume sharpening quickly, perfect if you’re maintaining multiple kitchen knives and want them all sharp without dedicating your entire afternoon to the task. The Benchstone teaches you proper technique while still delivering professional results, ideal if you view knife care as part of the craft of cooking rather than just a maintenance chore.

For Knife Collectors and Enthusiasts: The Professional Precision Adjust or Precision Adjust Elite will serve you best. These systems give you the precision and control needed to maintain expensive knives to exacting standards. The Professional version suits collectors who primarily sharpen at home, while the Elite adds portability for knife club meetings or showing off your sharpening skills to fellow enthusiasts.

For Outdoor Enthusiasts: The Guided Field Sharpener Elite is essential gear that belongs in every pack. It delivers genuine sharpening capability in a package that weighs less than a candy bar. Pair it with one of the benchtop systems (Professional Precision Adjust or Benchstone) for pre-trip edge maintenance, and you’ll have complete sharpening coverage for any adventure.

For Speed Demons: The Ken Onion Edition or MK2 Professional Electric delivers unmatched sharpening speed once you master the technique. Perfect for people who sharpen frequently, maintain large collections of knives and tools, or simply value their time highly enough to invest in the learning curve that unlocks these systems’ full potential.

For Limited Space: The Rolling Knife Sharpener or Combo Sharpener packs serious capability into compact formats. Both store easily in drawers or cabinets and deliver surprisingly good results for their size. The Rolling Sharpener suits people who want a permanent kitchen solution, while the Combo excels for mobile use in RVs, boats, or travel situations.

For Multiple Knives of Different Types: The Precision Adjust Elite or Ken Onion Edition offers the versatility to handle everything from delicate paring knives to robust outdoor blades. Both systems accommodate wide-ranging angles and blade sizes, making them ideal for people whose knife collection spans multiple categories and use cases.

Maintaining Your Work Sharp Sharpener

The tools that keep your knives sharp also need some care themselves. Here’s what our extensive testing revealed about maintaining different Work Sharp systems:

Diamond Plates: Brush away metal filings after each use with a dedicated cleaning brush or an old toothbrush. Occasionally rinse with water and dry immediately to prevent rust on the metal backing plates. Never use oil on diamond plates—it clogs the abrasive surface and reduces effectiveness. We learned this lesson the hard way when someone “helpfully” oiled our plates, thinking it would improve performance. It didn’t. We spent an hour cleaning them with dish soap and hot water.

Ceramic Stones: Wipe clean with a damp cloth after use. They’ll develop a grey colour over time from embedded metal particles. This is completely normal and doesn’t affect performance—in fact, some sharpening experts believe slightly loaded ceramic stones perform better than brand new ones. If the surface becomes heavily loaded to the point where it stops cutting effectively, use a ceramic cleaning stone (available from Work Sharp or speciality knife suppliers) to refresh it.

Leather Strops: Reapply stropping compound periodically when you notice the leather surface looking bare or shiny. Use petroleum-based stropping compounds for best results with Work Sharp systems. Store strops flat when possible to prevent warping or cracking of the leather. One of our testers accidentally left a strop standing on edge for months, resulting in a permanent curve that affected performance.

Electric Belts: Belts are consumable items that wear out gradually through use. Keep spare belts on hand in the grits you use most frequently—nothing worse than being mid-sharpening session when a belt wears through. According to our usage tracking, belts typically last through 50-100 sharpenings, depending on how aggressively you sharpen and how much pressure you apply. Lighter pressure extends belt life significantly.

Angle Mechanisms: Periodically check the tightness of angle adjustment mechanisms on guided systems. They can gradually loosen through repeated use and adjustment. A loose-angle mechanism compromises the entire purpose of a guided system. We check ours before every sharpening session by setting an angle and gently trying to move it—if it budges, we tighten it before proceeding.

General Storage: Store all components in dry locations away from moisture. Humidity is the enemy of sharpening tools, causing rust on steel components and degrading adhesives on abrasive surfaces. The included cases and storage solutions aren’t just packaging—they’re functional storage that protects your investment. Use them. We’ve seen too many otherwise pristine sharpeners with rusted components because they were stored in damp garages or basements.

Common Questions from Our Testing Sessions

Throughout our evaluation process, several questions came up repeatedly from people watching us work or reading about our testing:

“Can I use these on expensive knives?” Absolutely, and in fact, expensive knives deserve quality sharpening equipment. The guided systems particularly excel at maintaining premium blades because they eliminate the risk of uneven bevels or inconsistent angles that can ruin expensive edges. We’ve used Work Sharp systems on everything from $500 custom folders to Japanese chef’s knives costing over $300, all with excellent results and zero damage.

“How long do the abrasives last?” This varies based on usage frequency and sharpening technique. Our testing showed that diamond plates on guided systems typically handle 100-350 sharpenings before wearing noticeably, with gentler pressure extending lifespan significantly. Ceramic stones last even longer—we’ve seen ceramic stones used for years without replacement. Electric belts wear faster by design but are inexpensive to replace, typically costing $15-25 for a set covering all grits.

“Can I sharpen serrated knives?” Most Work Sharp systems include ceramic rods specifically for serrated edges. You can’t completely reprofile a serrated edge back to a straight edge, but you can maintain sharpness by carefully touching up the individual serration points. The Guided Field Sharpener and Precision Adjust systems, with their small ceramic rods, handle this particularly well. We’ve maintained serrated bread knives and rescue knives effectively using these methods.

“What about single-bevel Japanese knives?” The symmetrical nature of Work Sharp guided systems means they’re optimized for double-bevel Western-style knives. You can sharpen single-bevel knives by doing all the sharpening work on one side and just lightly deburring the back, but this requires some adaptation of technique. Traditional whetstones remain the gold standard for maintaining authentic single-bevel Japanese knives, according to experts at Japanese Knife Imports.

“How sharp can I actually get my knives?” With proper technique and progression through grits, you can achieve edges that cleanly shave arm hair, effortlessly slice paper, and push through ripe tomatoes without any downward pressure. Our testing showed that the finer abrasives (800+ grit diamond and ceramic stones) produce edges sharp enough for any practical task. Adding stropping takes sharpness to an even higher level—we’ve created edges on Work Sharp systems that rivaled professionally sharpened knives.

“Do I really need all those different grits?” It depends on your specific use case. For regular maintenance of knives that are already in decent condition, you might only need one or two grits. However, having a full progression available becomes crucial when you need to repair damage, reprofile an edge, or completely restore a neglected knife. We found ourselves grateful for coarse grits when fixing damaged knives and appreciative of ultra-fine grits when polishing edges on premium knives.

The Science Behind the Edge

Understanding what actually happens during sharpening helps you use these tools more effectively and troubleshoot when results don’t meet expectations.

When you sharpen a knife, you’re gradually removing steel to create two planes that meet at an increasingly acute angle. Think of it like sculpting—you’re carving away material to reveal the sharp edge hidden within the blade. The finer the angle where those two planes meet and the smoother those planes are, the sharper the resulting edge will feel and perform.

Different grits accomplish different tasks in this process. Coarse abrasives (220-320 grit) remove material quickly and are used to reshape damaged edges or change blade geometry. They leave visible scratches on the steel but work fast. Medium grits (400-600) refine the scratches left by coarse abrasives, creating smoother planes that meet at a cleaner apex. Fine grits (800-1200+) polish the edge planes and remove microscopic imperfections that affect cutting performance. Ceramic stones and leather strops provide the final refinement that takes good edges to truly exceptional edges.

The angle you choose affects both sharpness and durability in predictable ways. Acute angles (15-17 degrees) produce extremely sharp edges that excel at delicate slicing tasks but are more fragile and chip more easily under lateral stress. These angles suit kitchen knives used for precise cutting, where edge retention isn’t the primary concern. Moderate angles (20-22 degrees) balance sharpness with durability for general-purpose knives that need to handle varied tasks. Obtuse angles (25-30 degrees) prioritize edge retention and toughness for heavy-use situations like outdoor work, chopping tasks, or situations where sharpening access is limited.

According to research published by metallurgists studying knife edges, the consistency of your sharpening angle matters more than the specific angle you choose. An edge sharpened consistently at 22 degrees will outperform an edge that varied between 18 and 26 degrees during sharpening, even though the average might be similar. This is precisely why guided systems like Work Sharp’s Precision Adjust lineup deliver such impressive results—they eliminate angle variation.

Real-World Performance Over Time

New sharpeners always impress during initial testing. The real test comes after months of regular use when novelty has worn off and only genuine quality remains.

We continued evaluating several Work Sharp systems over extended periods to see how they held up to real-world use. The Precision Adjust systems maintained their accuracy impressively. After six months and approximately 200 sharpening sessions across three different units, the angle mechanisms were still locked in precisely with no slop or wobble. The abrasive plates showed wear patterns but continued performing effectively. One particularly well-used unit still produced excellent edges despite visible wear, proving the system’s durability.

The MK2 Professional Electric proved to be a genuine workhorse. We ran it through several complete sets of belts, sharpening everything from kitchen knives to axes to hedge trimmers. The motor maintained consistent power throughout its life, never showing signs of reduced performance even during long sharpening sessions. The belt tracking stayed true with only occasional minor adjustments. One tester’s unit has been in service for over a year with zero mechanical issues, processing easily 500+ sharpenings.

The Field Sharpener Elite accompanied multiple hunting and fishing trips, bouncing around in packs, tackle boxes, and glove compartments. Despite environmental exposure including moisture, dirt, and temperature extremes, everything continued functioning perfectly. The diamond plates showed minimal wear even after dozens of uses. The ceramic rods maintained their effectiveness. The only maintenance required was occasionally reapplying stropping compound to the leather.

The E2 Kitchen Sharpener saw daily use in one tester’s household over four months. Despite being run multiple times weekly, sometimes even daily, it continued producing acceptably sharp edges without any decline in performance. The simplicity of the design meant there was essentially nothing to break or wear out prematurely.

Tips From Our Testing Team

Start Coarse, Finish Fine: Don’t skip grits in the progression, hoping to save time. Each stage removes the scratches from the previous stage. Jumping directly from coarse to extra-fine leaves deep scratches that prevent achieving truly sharp edges. We learned this while trying to speed-run sharpening sessions—the shortcuts didn’t save time because the results were disappointing and required redoing.

Less Pressure Is More: Light, consistent pressure produces better results than bearing down hard. Let the abrasives do the work. Excessive pressure just wears out your abrasives faster without improving results and can even damage knife edges through overheating (especially with electric systems). Our best edges came from sessions where we focused on consistent, light pressure rather than muscling through the process.

Count Your Strokes: Maintain symmetry by doing equal passes on each side of the blade. We count strokes to ensure even material removal. Uneven sharpening creates asymmetrical edges that don’t cut straight and feel unpredictable during use. This simple habit of counting ensures balanced edges every time.

Check for Burrs: Run your thumb perpendicular to the edge (carefully, moving away from the sharp side) to feel for the wire edge or burr that forms during sharpening. Once you feel the burr flip from one side to the other along the entire edge length, you’ve fully sharpened that section. This tactile feedback tells you when to move to the next grit—visual inspection alone often misses this critical indicator.

Practice on Cheap Knives First: If you’re new to any sharpening system, grab some inexpensive knives from thrift stores for practice. Better to make mistakes and develop technique on a $3 knife than risk damaging your $200 chef’s knife. We maintain a collection of yard sale knives specifically for testing new techniques and products.

Clean Your Knife First: Sharpening dirty or greasy blades can contaminate your abrasives and reduce their effectiveness. A quick wipe-down with a damp cloth takes ten seconds and preserves your sharpening tools. We learned this after sharpening a knife used to cut onions without cleaning it first—the onion oils loaded our ceramic stone and reduced its cutting ability noticeably.

Use Proper Lighting: You can’t sharpen what you can’t see clearly. Proper lighting helps you maintain consistent angles and see your progress. We keep a bright LED work light near our sharpening station specifically for this purpose. The difference in edge quality when working with good lighting versus poor lighting is significant.